I got some emails requests on how to photograph such a tiny models.

I got some emails requests on how to photograph such a tiny models.I could say the technique is all in the lights, but the camera settings has a lot to do with the results also.

I got some ideas from the following sites.

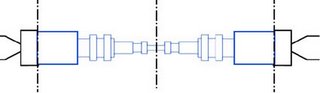

Light box / light tent

Photographing miniatures

Indoor photography

DIY lightbox

Basically I've chosen a “no flash” setting with the macro option enable on my Canon A95, the macro setting is usually represented by a tulip logo.

Basically I've chosen a “no flash” setting with the macro option enable on my Canon A95, the macro setting is usually represented by a tulip logo.Without the direct reflection of lights, with the help of the paper rolls over the neon’s, you have a crisper image quality. But you must use a steady hand or a tripod for such a low light setting.

So basically it is done with the following points only.

- Paper light filtering (just 2 sheets of paper rolled)

- No flash

- Macro setting

- No hands shaking allowed.